The Haleys and Walter Przybylek specialized in a glass design process called “cast figure molding,” a process Reuben Haley is credited with perfecting and which involved several distinct steps centered on an initial design concept sculpted in clay. Designing in clay allowed fine details to be incorporated from the outset of a project. A plaster cast was produced from the clay model, which in turn would be released to a foundry to produce an iron mold. Iron molds were then used in the glass factories to enable mass production. From start to finish, the design and production process required a mix of creative vision, artistic skill, and deep technical knowledge. Finished designs not only reflected the initial conceptual design and artistic elements. They also illustrated specific know-how emphasizing “design for manufacture” concepts, including the evaluation and placement of mold parting lines, and often reflected numerous design and process iterations that optimized manufacturing efficiency within both the foundry (iron molds) and the glass factory (finished pieces).

In interviews later in his life with authors such as Jack Wilson, Ken Haley recalled his father’s work and dedication in training a trio of cast figure mold pattern makers – Walter Przybylek, Virgil Loomis, and Bill Del Monico – who followed Reuben, and then Kenneth, as they moved between companies. Walt was one of those mold makers who got his start in the glass industry as an apprentice in Reuben Haley’s studio, working closely with Reuben and his son Ken for many years. As Reuben or Ken changed employers or established independent studios, the mold makers maintained their ties with the Haleys and continued their ongoing partnerships. Among these colleagues, Walt’s closest relationship was with Bill Del Monico. Bill often visited Walt at his studio and lent a hand when the workload was heavy for Walt, and the two collaborated or exchanged notes and advice on a variety of projects over a friendship spanning many years.

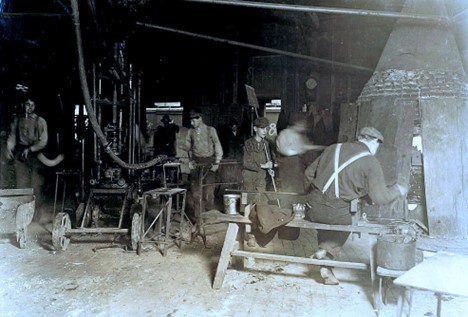

On a day to day basis, mold makers worked in partnership with glass designers, ensuring that the creative vision developed in the design process could be successfully translated into quality glass products capable of successful mass production. The entire process - from initial concept to finished glass piece - involved painstaking craftsmanship in multiple mediums, including paper drawings, clay and plaster sculptures, complex metalwork (i.e., design of iron molds) and finished glass work. Mold makers served a crucial role in the process, enabling artistic concepts to become real physical products.

Beyond artistic skills, mold makers needed to develop a working technical knowledge of multiple industrial functions, including the design of foundry patterns and the likely behavior and cooling characteristics of molten glass within the mold. They also had to be skilled communicators, helping to coordinate the actions of multiple players along the entire process chain – including the end customer, designer, and foundry personnel. Sometimes, this involvement even stretched to the factory floor of the glasshouse. When needed, mold makers assisted technical staff and production personnel with trouble-shooting when newly-designed or re-designed molds went into production.